Stainless steel centrifugal pump

Product parameters

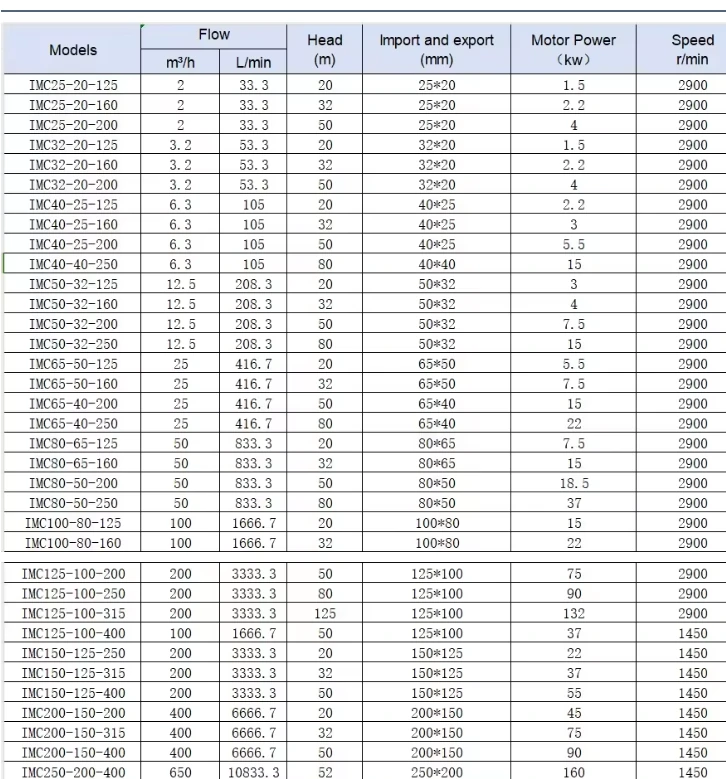

Flow Range:

Head Range:

Power Range:

Temperature resistant range:

Range of inlet and outlet caliber:

Material:

1m³/h-800m³/h

10m-130m

1.1kw-160kw

<100℃

DN25-DN250

304/316

The IMC centrifugal pump is a type of vane pump. As this pump operates by the high-speed rotation of the impeller causing the blades to push the liquid to rotate, thereby obtaining centrifugal force and completing the pump’s transportation process, it is called a centrifugal pump.

Centrifugal pumps have a wide range of applications and are almost indispensable equipment in water environmental pollution control systems. Most urban sewage treatment relies on centrifugal pumps to raise water levels and ensure the smooth progress of subsequent treatment

Carry out; The treatment of industrial wastewater also relies on the pressurization of centrifugal pumps to achieve water flow. As a centrifugal pump is an important power equipment, it will consume a large amount of power during operation. Therefore, it is reasonable,

The economical selection and use of centrifugal pumps is an important aspect of reducing the cost of sewage treatment, especially for urban sewage treatment plants. The working principle: The reason why a centrifugal pump can draw water (or other fluids)

The body is sent out due to the effect of centrifugal force. Before the centrifugal pump starts working, the pump body and the inlet pipe must be filled with water. When the impeller rotates rapidly, a vacuum area (low-pressure area) is formed at the suction inlet of the impeller, and the liquid

The body (water) is sucked into the impeller; After entering the impeller, water rotates rapidly along with it. Under the action of centrifugal force, the rotating water moves radially and flies away from the impeller outlet, forming water discharge. When the impeller rotates, it will be capable

The volume is transferred to the water entering the impeller, causing the water to generate velocity energy and pressure energy. When it flows to the impeller outlet, the pressure energy of the water becomes the maximum value. This is the total head produced by the centrifugal pump. The basic structure is the foundation of a centrifugal pump

This structure is mainly composed of four parts: the impeller, the pump body, the pump shaft and bearings, and the shaft sealing device. The impeller is the core component of a centrifugal pump. Its function is to transfer the mechanical energy of the prime mover to the liquid, thereby increasing the static pressure of the liquid

Energy and kinetic energy have been enhanced. Because of its high rotational speed, it needs to pass a static balance test before assembly. The inner and outer surfaces of the impeller are required to be smooth to reduce the frictional loss of water flow. The pump body is also called the pump casing because there is one inside the casing

A snail shell-shaped channel with a gradually expanding cross-section, also known as a volute, is the main body of the water pump, serving to support and fix it, and is connected to the bracket for installing the bearing. The function of the pump shaft is to be driven by a coupling and electric power

It is connected to the motor and transmits the torque of the motor to the impeller, so it is the main component for transmitting mechanical energy. Bearings are components that are sleeved on the pump shaft to support it. There are two types: rolling bearings and sliding bearings.